- Can I use a Tote for Mixing?

Yes. IBCs (Intermediate Bulk Containers), or more commonly known as Totes, can be structurally strong enough for substantial mixing. This can result in a very economical process vessel, but only with a high pumping mixer design.

Big challenges that are unique to tote mixing are getting the correct impellers into the tote or IBC, fully involving the tote, proper and complete blending and suspending solids. Many of these challenges are related to using "off the shelf" or high rpm mixers for totes.

Dynamix has recognized that the products in totes are just as important to your process as the process itself. We have designed a full line of impellers specific to IBC Tote Mixing, and our application team will further configure these mixers to address all of these challenges as well as others unique to your product or IBC mixing requirement.

- How do I choose the right tote mixer for my needs?

The choice of a tote mixer depends on several factors:

- Impellers: The correct mixer design always starts with the correct impeller selection, and this is never more relevant than with an IBC Mixer. Plastic Totes and IBCs often have small 6-inch openings. These pose a specific challenge to proper mixing. True axial flow mixing and control will require larger diameter impellers than the six-inch opening. For this Dynamix has developed a full line of 4 blade collapsible impellers which are unique to our company.

- Volume: IBCs or intermediate bulk containers come in many different volumes and shapes. Dynamix has developed a full line of 4 blade collapsible impellers which can be sized to offer the axial flow and turnover rates to properly mix your IBC and Tote.

- Viscosity: This is defined as the resistance to flow, which is a critical part of mixing. Understanding how Torque, Pumping, and Impellers relate to proper flow helps you realize the importance of having one of our application engineers design and select a Tote Mixer for your specific application. Viscosity is one of the key elements to address when looking to mix in a tote. Dynamix can help design a tote mixer for the highest viscosities.

- Material compatibility: Ensure the mixer is made of materials compatible with your product (e.g., stainless steel for food-grade applications).

- Speed and power requirements: Choose a mixer that can handle the required agitation speed and mixing intensity.

- Environment: Whether the mixer needs to be explosion-proof, for example, in hazardous areas.

- What are the common applications of tote mixers?

Tote mixers are used in industries such as:

- Food & Beverage: This industry has many opportunities for mixing in totes. Both for shipping and processing food and beverages often use totes or IBCs. Unfortunately, there have been a lot of "off the shelf" mixers or high rpm (>300rpm) tote mixers used which did not work. Dynamix recognizes the potential for tote mixing in Food and Beverage industry, and can enable the industry to use IBC and Totes for mixing in many higher viscosity and solid suspension or low shear applications.

- Water Treatment: To prepare admixtures, coagulants, chlorination, flocculants, and polymers.

- Chemical processing: To mix chemicals or reagents.

- Pharmaceutical: To ensure uniform distribution of ingredients in liquid formulations.

- Paints and Coatings: To mix pigments and other components. Solvent-borne and water-based paints.

- Cosmetics: For creating consistent formulations of lotions, creams, and other products.

- Mining and Mineral Processing: For reagents, tailings, flocculants, cyanide, and sludge.

- Pulp and Paper: A critical design for clay suspensions, fillers, green liquor, and black liquor.

- Oil and Gas: Fracturing fluids, down-hole agents, drilling mud, polymer supply, and coagulants.

- What are the safety considerations when using a tote mixer?

Safety when using tote mixers is crucial. Some safety considerations include:

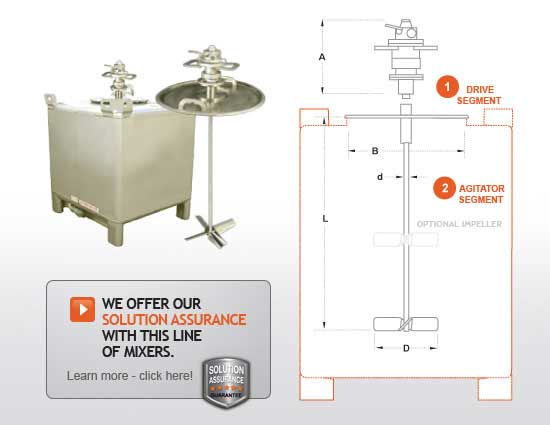

- Exposed rotation is an important safety hazard in many tote mixer designs. Bridge designs or other couplings often leave the mixer shaft exposed to the Operator. Entanglement is a serious threat as the operators often work intimately with the mixer. A Dynamic coupling like the one used on the Integrated Tote Mixer (ITM) is essential to completely enclosing the shaft and rotation. There is no exposed rotation with this design.

- Electrical safety: Ensure proper grounding of electric mixers.

- Explosion-proof designs: For mixing flammable environments and substances, ensure that the mixer is rated for use in explosive environments.

- Fully enclosed Mixing: product exposure to the environment and operators can be harmful with many products that are shipped in IBC’s or Tote Containers. Opening the tote or IBC or mixing the IBC while open can be very dangerous with many fluids. The ITM can completely eliminate this safety hazard. The Integrated Tote Mixer (ITM) completely encloses the mixer inside of the Tote or IBC so that mixing can occur without exposure to the environment or operators, which is a serious safety improvement. Furthermore, the Tote and Product can be shipped with the mixer already in the IBC or Tote. Suppliers can protect their end user environment, and operators by supplying their product in IBC’s with an Integrated Tote Mixer (ITM) mixer segment already installed in the tote.

- Personal protective equipment (PPE): Operators should wear PPE, such as gloves and goggles, to prevent exposure to harmful chemicals or accidental splashes.

- How do I clean a tote mixer?

Cleaning procedures depend on the type of materials used, but generally:

- Disassemble the mixer: Remove the mixing components and rinse thoroughly.

- Use appropriate cleaning agents: Use food-safe or industrial-grade cleaning solutions depending on the material.

- Sanitization: For food or pharmaceutical applications, thorough sanitization is required to ensure no contamination between batches.

- Dry thoroughly: Ensure that the mixer is dry before reusing to avoid rust or contamination.

- Are tote mixers portable?

Many tote mixers are designed to be portable, allowing them to be moved between different containers or production areas. Common bridge-mounted tote mixers require a forklift or other machinery to relocate the tote mixer.

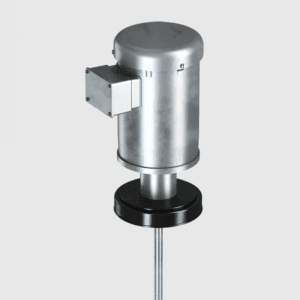

The ITM Tote Mixer is uniquely designed to be moved, installed and removed by a single person. The Integrated Tote Mixer includes a Drive Segment (Motor: Air or Electric) and an Agitator Segment (Impeller and Shaft), which can be carried by a single person in each hand. Installing the Agitator Segment into the Tote, locking the Agitator Segment into place, then coupling the Drive Segment to the Agitator Segment. This is particularly useful in small or medium-sized operations where mixers may need to be relocated for different tasks. This unique design offers all the mixing benefits of the ITM anywhere it can be carried.

So yes, the ITM is Portable, and portable like no other design.

- How do I maintain a tote mixer?

Tote Mixers should not require significant maintenance outside of what is required by the motor and drive type you select.

The ITM Tote Mixer is designed with the same robust service factors and materials as all the Dynamix Industrial Agitators. We do not consider Tote Mixing a commodity process. Every product and process are significant, and mixing in totes for product or process quality is just as important as the process itself.

For this reason, we use large service factors in our drive selection. Cycloidal gearboxes offer compact design, and massive shock load ratings. With a dual bearing configuration, these mixers are ready for the most rugged and demanding applications with little or no maintenance.

Regular maintenance can include:

- Lubricate moving parts: Cycloidal gearboxes are sealed for life lubrication. No need to lubricate.

- Check for wear and tear: Regularly inspect the impellers, seals, and motor for signs of damage. Operation after damage can greatly impact and damage other components of the Tote Mixer

- Clean regularly: Keep the mixer clean to avoid overheating. Impeller balance is important to proper operation, so be sure not to allow build up of rags or other products on impellers.

- Monitor motor performance: Periodically check the motor and electrical components for optimal performance.

- What mounting options are available for Dynamix’s tote mixers?

Our tote mixers have several mounting options, including bridge mounts and cap mounts, allowing for versatile installation to suit different tote designs and application needs.

- Can I use a tote mixer for different container sizes?

Yes, tote mixers are designed to work with various tote sizes, ensuring flexibility across different mixing applications. Our commitment to proper mixer design means that we will configure your tote mixer for the correct container volume, opening type, height, width, and application.

- What are the primary benefits of the Integrated Tote Mixer (ITM)?

The ITM offers a guaranteed performance by using innovative 4-bladed collapsible impellers. These impellers allow large, controlled mixing inside the confined space of a tote, converting it into a process tank while ensuring no contamination during mixing. The Integrated Tote Mixer is also portable and easy to install.

- How does the collapsible impeller on the ITM work?

The collapsible impeller is designed to fit through small openings in totes, allowing large blades (up to 20 inches) to unfold once inside. This ensures efficient mixing that is typically seen in larger industrial mixers.

- Can I use one mixer across multiple totes?

Yes, thanks to the dynamic drive coupling, a single drive unit can be attached to different totes, making it portable and reducing cross-contamination risks by using independent agitator segments.

- How do I know which mixer configuration is right for me?

Dynamix provides custom design consultations and works with customers to select the optimal mixer configuration for their specific process and budget.

- Can these tote mixers be used for different industries?

Yes, tote mixers are versatile and can be used in industries like automotive, chemical processing, water treatment, and more, ensuring product quality control and efficient mixing.

- How long do tote mixers last?

With proper maintenance, a well-built tote mixer can last for many years, often 10 to 15 years, or longer. The lifespan will depend on the intensity of use, maintenance routines, and operating conditions.

Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website