- Q: What makes non-Newtonian fluid mixing difficult?

A: Their viscosity changes under shear, temperature, or time, requiring adaptive design strategies.

- Q: What type of impeller should I use for high-viscosity fluids?

A: Helical ribbons, anchors, or dual impellers depending on shear sensitivity and tank size.

- Q: Can I monitor viscosity in real-time?

A: Yes. Inline sensors linked to SCADA systems provide real-time data.

- Q: What is rheology and why does it matter?

A: It’s the study of material flow. Understanding rheology helps in designing mixers that don’t under- or over-process the fluid.

- Q: Where can I learn more?

A: Visit AIChE and ISA Automation Events.

Mixing Non-Newtonian & High-Viscosity Fluids: Strategies for Shear, Temperature & Rheology Control

Understanding the Complexity of Non-Newtonian and High-Viscosity Fluid Mixing

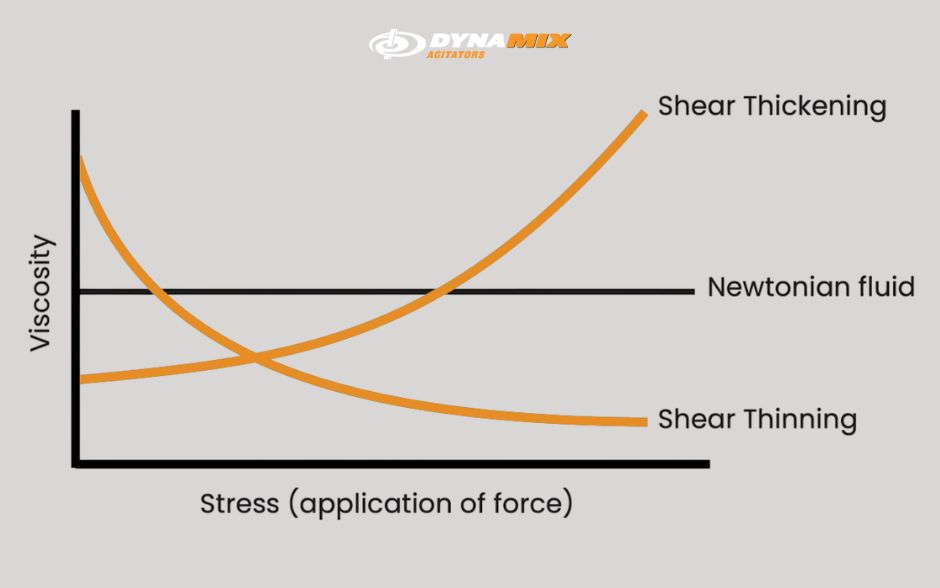

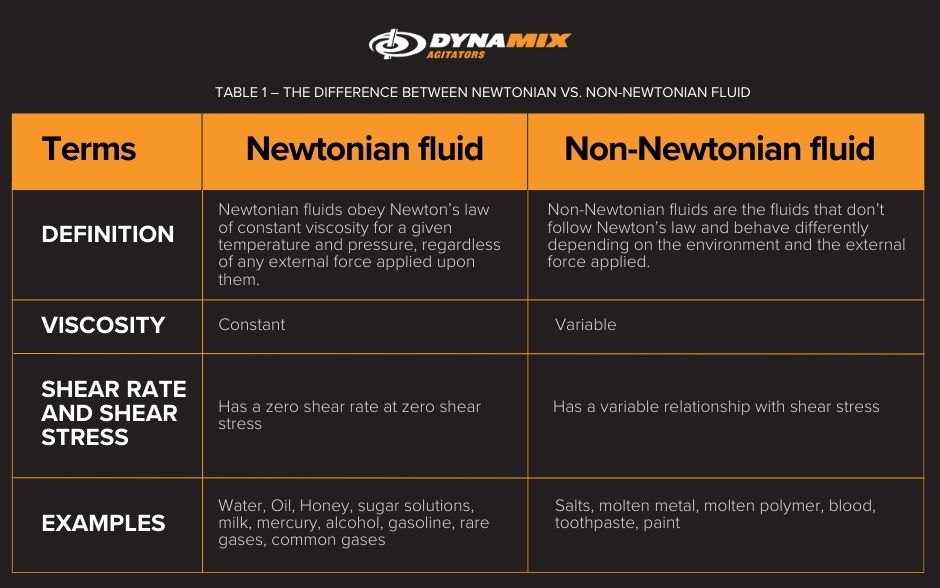

Mixing non-Newtonian and high-viscosity fluids presents a unique set of engineering challenges. These materials don’t behave in predictable ways under stress. Unlike Newtonian fluids (like water or mineral oil), their viscosity can change based on shear rate, temperature, and time.

From cosmetics and coatings to food products and polymers, mastering the art of shear, temperature, and rheology control is key to product consistency, quality, and process efficiency.

To understand the equation behind shear mixing and the different variables,

What Are Non-Newtonian Fluids?

Non-Newtonian fluids defy the constant-viscosity rule. They fall into categories such as:

- Shear-Thinning (Pseudoplastic): Viscosity decreases with shear (e.g., ketchup, paints)

- Shear-Thickening (Dilatant): Viscosity increases with shear (e.g., cornstarch slurry)

- Thixotropic: Viscosity decreases over time under shear (e.g., printing ink)

- Rheopectic: Viscosity increases over time under shear (rare)

Rheology and Its Role in Mixing Designs

Rheology is the study of flow and deformation of matter. When dealing with non-Newtonian or high-viscosity fluids, rheological data is essential for designing a mixing system that performs predictably.

Key metrics include:

- Apparent Viscosity: The observed resistance at a specific shear rate

- Yield Stress: The force required to initiate flow

- Flow Index (n) and Consistency Index (k) from the Power Law model.

Challenges in Mixing High-Viscosity and Non-Newtonian Fluids

- Inconsistent Shear Zones: Impellers may not provide uniform shear

- Dead Zones: Ineffective circulation in high-viscosity systems

- Temperature Control: Viscosity may shift with thermal changes

- Settling and Separation: Multiphase fluids can stratify.

Strategies for Shear Management

1. Impeller Selection:

- High-shear impellers (e.g., rotor-stator, Rushton turbines) for shear-thickening fluids.

- Low-shear impellers (e.g., anchor, helica ) for shear-sensitive applications.

2. Variable Speed Drives (VFDs):

- Allow fine-tuning of shear rate.

- Essential for process development and scale-up .

3. Axial vs. Radial Flow:

- Axial flow improves top-to-bottom circulation.

- Radial flow enhances localized shear .

Temperature Control: Managing Thermal Sensitivity

Many non-Newtonian fluids change viscosity dramatically with temperature. Therefore, maintaining a stable thermal environment is essential.

Design tips include:

- Jacketed Tanks: Maintain constant temperature

- External Heat Exchangers: For temperature-sensitive fluids

- Sensor Integration: Inline temperature probes for real-time control

The Role of Customization at Dynamix Agitators

At Dynamix Agitators, understanding the rheology of your fluid is the first step in custom mixer design. Whether handling a pseudoplastic slurry or a thixotropic gel, Dynamix:

- Designs impellers that optimize shear and prevent overmixing.

- Configures tank geometries to eliminate dead zones.

- Integrates temperature and viscosity sensors for dynamic control.

Dynamix’s customer-centric engineering ensures that every mixing challenge is met with precision and reliability.

Case Studies: Real-World Solutions

- Paint Manufacturer: Improved pigment dispersion and reduced cycle time by 22% with a dual-impeller setup and VFD.

- Adhesives Plant: Prevented polymer breakdown with low-shear anchors and thermal stabilization.

- Food Processor: Maintained texture and viscosity with CIP-compatible ribbon mixers and inline monitoring.

Learn more from events like INTERPHEX.

Mixer Sizing for Non-Newtonian Fluids

- Use the Metzner-Otto method to determine effective Reynolds number for non-Newtonian systems.

- Consider impeller clearance, tip speed, and power input.

- Match motor torque to worst-case viscosity conditions.

Integrating Automation and Feedback Control

Smart systems enhance repeatability and cut downtime. Tools include:

- SCADA Integration

- Torque Monitoring

- Viscosity Feedback Loops

- Automated Recipe Management

PACK EXPO showcases smart mixer integration.

Conclusion: Mastering Complexity with Smart Design

Mixing non-Newtonian and high-viscosity fluids is an engineering art form. By carefully managing shear, controlling temperature, and accounting for rheological behavior, manufacturers can unlock consistency and efficiency.

Dynamix Agitators offers mixers that are not only mechanically sound but tailored to your process realities. Learn more about our custom solutions by filling out our Request a Quote form.

FAQ's

How Baffle Arrangement Improves Industrial Mixing

Do I need baffles in my Mixing Tank? Yes! While

Preventative Mixer Maintenance: A Checklist for Industrial Mixer Care

Industrial mixers are critical assets in chemical, food, pharmaceutical, and

Environmental Factors To Consider When Designing a Mixer

Why Environment Matters in Mixer Designs In the industrial

Other Recent In The Mix Articles:

Search :

SELECT THE BLOG CATEGORY BELOW

Categories

- Coal Mining (1)

- Crop Protection (1)

- Dynamix Products (7)

- Explosion Proof Motors (1)

- Fertilizer Mixer (1)

- Hand Sanitizers (1)

- Industrial Mixing (53)

- Mechanical Seals (1)

- Mining & Mineral Processing (1)

- Mixer Configuration (25)

- Mixing 101 (24)

- Mixing at Home (5)

- Mixing Principles in Play (9)

- Oil & Gas (1)

- Tank Configuration (4)

- Tote Mixing (2)

- Update (1)

- Water Treatment (28)

- Water Treatment Books (6)

- Water Treatment Innovation (13)

WHAT OUR CUSTOMERS ARE SAYING

Keep up with what's new at Dynamix

Subscribe to our newsletter for helpful technical publications and industry announcements.