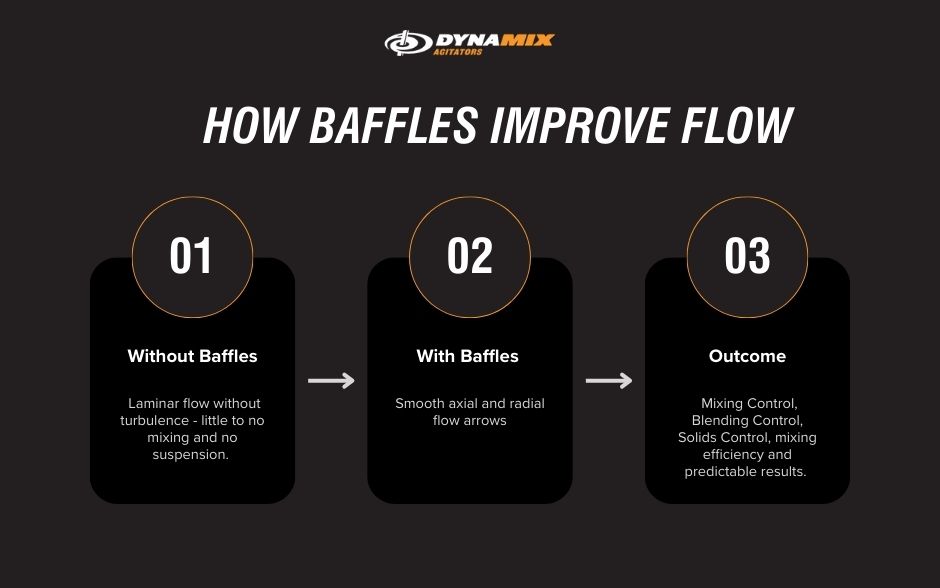

- Q: What problem do baffles solve in industrial mixing?

A: Baffles address undesirable flow patterns caused by and circular motion in tanks. By disrupting rotational flow, they eliminate dead zones, improve agitation, and promote uniform mixing, resulting in better product quality mixing control and process consistency.

- Q: What are baffles, and how do they function?

A: Baffles are typically flat plates installed along a tank’s walls or bottom to interrupt swirling motion. They redirect liquid flow from circular to axial and radial patterns, enhancing fluid movement, mixing efficiency, and solids suspension.

- Q: What are the key benefits of using baffles in a mixing tank?

A: Baffles help:

- Create mixing control

- Enable blending controls

- Prevent vortex formation and air entrainment

- Improve solid suspension and prevent settling

- Enhance gas dispersion in aeration processes

- Ensure even ingredient distribution throughout the tank.

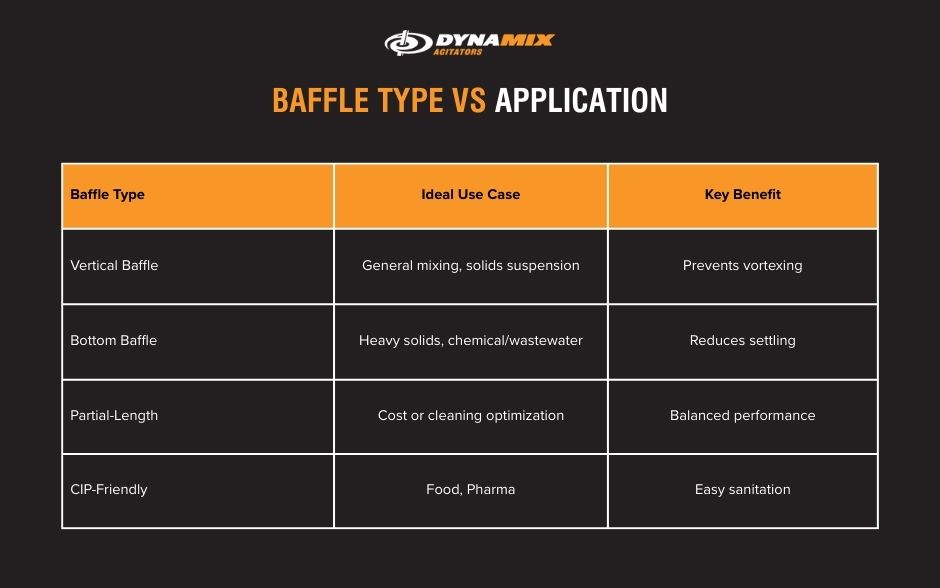

- Q: What are the most common types of baffle designs?

A: The four main types are:

- Standard Vertical Baffles – best for general mixing and solids suspension

- Bottom Baffles – ideal for keeping heavy solids in suspension

- Self-Baffling mixer designs – increased mixer costs while increasing turbulence

- Removable or CIP-Friendly Baffles – designed for sanitary industries like food and pharmaceuticals.

- Q: How many baffles should a typical mixing tank have?

A: Most tanks perform best with four equally spaced baffles, each approximately 1/12 of the tank’s diameter. However, smaller tanks, totes, or specialized systems may require adjusted dimensions or fewer baffles.

- Q: What industries benefit most from using baffles in mixing systems?

A: Baffles are used across multiple industries, including:

- Food & Beverage – preventing stratification in dairy and sauces

- Pharmaceuticals – achieving homogeneity in suspensions

- Chemical Processing – improving dispersion and reaction uniformity

- Wastewater Treatment – maintaining movement of flocculants and solids.

- Mining and Mineral Processing – critical design for solids suspension, sparging and reactions

- All – all mixing applications in the Turbulent to Transitional mixing regimes will benefit from baffling

- Q: How do baffles improve solids suspension and prevent settling?

A: Baffles redirect liquid motion from circular to an Axial upward and outward flow, ensuring solids are lifted and remain suspended throughout the tank. This consistent movement prevents accumulation at the bottom and enhances overall blending efficiency.

- Q: Why are removable or CIP-friendly baffles important for sanitary applications?

A: In food and pharmaceutical processing, removable or polished baffles allow for clean-in-place (CIP) sanitation, preventing cross-contamination and ensuring compliance with FDA and GMP hygiene standards.

- Q: How does baffle configuration affect energy efficiency?

A: Properly designed baffles enhance mixing efficiency and fluid motion, allowing mixers to achieve the same results at lower speeds and energy levels. This reduces operating costs while maintaining consistent product quality. This also increases the time to uniformity requiring less energy.

- Q: How does Dynamix Agitators optimize baffle design for customers?

A: Dynamix Agitators engineers custom baffle configurations tailored to tank geometry, mixer type, and process requirements. Their designs improve mixing efficiency, reduce energy use, and ensure reliable, application-specific performance across all industries.

How Baffle Arrangement Improves Industrial Mixing

Do I need baffles in my Mixing Tank? Yes! While a mixer is at the heart of your mixing process, the tank design can make or break the process. One of the most common overlooked elements of mixer tank design is Baffle Design. Even with a properly sized mixer, fluids often swirl with no turbulence. This is not mixing. This leads to dead zones, poor suspension, and inconsistent product quality – no mixing control.

The solution is simple but powerful: baffles. By disrupting circular flow, baffles improve agitation by creating turbulence, and enhancing axial flow. This offers great benefits in solids suspension, blending, time to uniformity and energy efficiency.

What Are Baffles?

Baffles are typically flat plates installed along the walls of a mixing tank. They interrupt the natural tendency of fluid to simply move with the impellers. Avoiding swirling motion of fluids, converting rotational flow into more effective axial and radial flow patterns.

Key benefits of baffles:

- True Axial Flow in a time-controlled approach

- Control vertexing and air entrainment

- Control suspension of solids

- Enhance gas dispersion in aeration processes

- Ensure uniform distribution of ingredients

- Control Surface motion

See Dynamix’s Mixer Systems for engineered solutions with optimized baffle configurations.

Common Baffle Designs

1. Standard Vertical Baffles

The most common type, vertical baffles run along the tank wall from top to bottom.

- Best for general mixing, blending, and solids suspension

- Prevent large-scale swirling in tall tanks

It is critical to balance this design with the process. Rules of thumb given below are only part of the design.

2. Bottom Baffles

Installed at the tank bottom, these help reduce settling in tanks with flat or dished heads.

- Useful in chemical mixing and wastewater treatment

- Control heavy solids in suspension

3. No Baffles

It is not always possible to have Baffles. In these cases, proper mixing design or other tank designs can be incorporated. Not all tanks require full-length plates. Shorter baffles are used in certain applications to balance cost, flow control, and cleaning needs.

4. Removable or CIP-Friendly Baffles

In food and pharmaceutical industries, removable baffles or polished designs allow for clean-in-place (CIP) sanitation without cross-contamination risks.

How Many Baffles Are Needed?

Most tanks require four equally spaced baffles, typically sized at 1/12 of the tank diameter. However, smaller tanks or tote applications may require modified designs.

For engineering guidance, consult with a Dynamix Application Engineer. Wall gaps and location to surface and tank bottom/shape are required for on an application-to-application consideration.

Industry Applications of Baffles

- Food & Beverage – Preventing stratification in dairy, sauces, and beverages

- Pharmaceuticals – Ensuring homogeneity in suspensions and solutions

- Chemical Processing – Improving reactions and dispersions in solvents or slurries

- Wastewater Treatment – Keeping flocculants and solids in motion

- Mining and Mineral Processing – critical design for solids suspension, sparging and reactions

Learn more about Industry Mixing Applications.

Final Thoughts

Baffles are a small design feature with a big impact. They need to be designed with the mixer, and for the process. By disrupting the natural flow of fluid with the impeller baffles improve agitation by creating turbulence and enhancing axial flow. This is a critical part of controlling solids suspension, blending, time to uniformity and energy efficiency.

At Dynamix Agitators, we design and specify the baffles for you. Our Application Engineering Team will Custom baffle configurations tailored to your tank size, mixer type, process and industry requirements—helping you achieve reliable, efficient mixing every time.

FAQ's

How Baffle Arrangement Improves Industrial Mixing

Do I need baffles in my Mixing Tank? Yes! While

Preventative Mixer Maintenance: A Checklist for Industrial Mixer Care

Industrial mixers are critical assets in chemical, food, pharmaceutical, and

Environmental Factors To Consider When Designing a Mixer

Why Environment Matters in Mixer Designs In the industrial

Other Recent In The Mix Articles:

Search :

SELECT THE BLOG CATEGORY BELOW

Categories

- Coal Mining (1)

- Crop Protection (1)

- Dynamix Products (7)

- Explosion Proof Motors (1)

- Fertilizer Mixer (1)

- Hand Sanitizers (1)

- Industrial Mixing (53)

- Mechanical Seals (1)

- Mining & Mineral Processing (1)

- Mixer Configuration (25)

- Mixing 101 (24)

- Mixing at Home (5)

- Mixing Principles in Play (9)

- Oil & Gas (1)

- Tank Configuration (4)

- Tote Mixing (2)

- Update (1)

- Water Treatment (28)

- Water Treatment Books (6)

- Water Treatment Innovation (13)

WHAT OUR CUSTOMERS ARE SAYING

Keep up with what's new at Dynamix

Subscribe to our newsletter for helpful technical publications and industry announcements.