- Q: Why is preventative maintenance important for industrial mixers?

A: Preventative maintenance ensures consistent performance, longer service life, and reduced downtime for industrial mixers. Regular inspections help avoid costly repairs and can maintain compliance with GMP and FDA standards in regulated industries like pharmaceuticals and food processing.

- Q: What are the consequences of neglecting mixer maintenance?

A: Without routine maintenance, mixers can experience wear, vibration, and misalignment, leading to mixer failure, unplanned downtime, and increased energy consumption. Neglecting care often results in premature part failure and higher operating costs.

- Q: How often should impellers be inspected?

A: Impellers should be inspected regularly for cracks, chips, or misalignment. Worn or damaged blades reduce efficiency and create uneven flow patterns. Checking impeller condition is one of the most critical steps in any mixer maintenance program.

- Q: Why are seals and bearings so important in mixers?

A: Seals prevent leaks, hold pressure and protect from contamination, while bearings minimize friction and wear. Over time, both components degrade, so routine inspection, lubrication, and timely replacement are key to avoiding mechanical failure and maintaining sanitary operation.

- Q: What should be included in motor and drive maintenance?

A: Mixer power systems should be routinely checked for oil levels, leaks, and proper amperage draw. Verify that VFDs (Variable Frequency Drives) operate correctly and that explosion-proof motors remain compliant for hazardous environments.

- Q: How do you maintain sanitation in mixers used for food or pharmaceutical applications?

A: Use CIP (clean-in-place) systems, appropriate finishes such as electropolished finishes, and follow FDA/GMP cleaning protocols. These practices ensure hygienic operation, prevent contamination, and make cleaning faster and more effective.

- Q: How can you detect and fix shaft misalignment in a mixer?

A: Symptoms of misalignment include excessive vibration, unusual noise, and premature bearing wear. Check shaft positioning and balance during regular maintenance. If imbalance is detected, the impeller may need rebalancing or replacement to prevent damage. Contact Dynamix Agitators immediately.

- Q: Why should spare mixer parts be kept in stock?

A: Having a spare parts inventory—including impellers, seals, bearings, and gear reducers—minimizes downtime during maintenance or emergency repairs. Partnering with a mixer supplier for a preventative parts program ensures quick replacements.

- Q: How does Dynamix support preventative maintenance programs?

A: Dynamix Agitators provides engineering guidance, spare parts management, and maintenance planning support. Their expertise helps manufacturers extend mixer lifespan, improve performance, and maintain compliance with GMP and FDA regulations.

Preventative Mixer Maintenance: A Checklist for Industrial Mixer Care

Industrial mixers are critical assets in chemical, food, pharmaceutical, and specialty manufacturing. When properly maintained, mixers deliver reliable performance, consistent product quality, and long service life. But without regular care, even the most durable equipment can suffer costly breakdowns.

This guide outlines a preventative maintenance checklist for mixers helping you reduce downtime, extend equipment life, and protect your investment.

Why Preventative Maintenance Matters

Mixers operate under tough conditions: high torque, variable viscosities, abrasive slurries, and continuous duty cycles. Over time, wear and misalignment can lead to:

Inconsistent mixing performance

Unplanned downtime

Costly part replacements

Reduced efficiency and higher energy use

Proactive maintenance not only prevents breakdowns but also improves efficiency and ensures compliance with GMP and FDA standards in regulated industries.

Learn more about mixer performance in Dynamix’s Mixer Systems Overview.

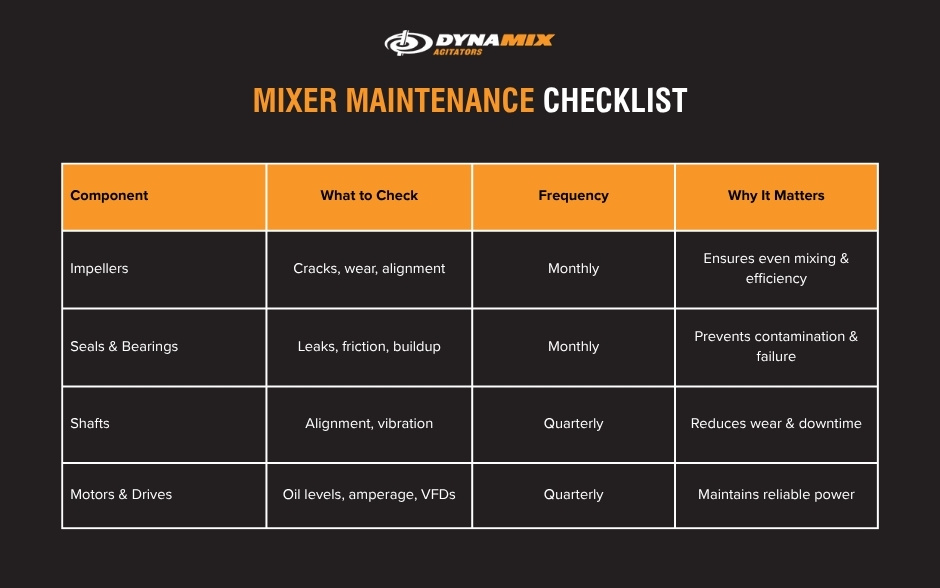

Industrial Mixer Maintenance Checklist

1. Inspect Impellers

Impellers are the workhorses of mixing. Regular inspection ensures:

Any form of Build up which can create an imbalance on blades

No cracks, chips, or wear on blades

Correct alignment within the tank

Proper sizing for current fluid viscosity

Imbalanced or damaged impellers will accelerate shaft and bearing damage rapidly. Turn off your mixer as soon as any excess vibration results.

2. Check Seals & Bearings

Seals prevent leakage and contamination, while bearings reduce friction. Over time, both wear down. Maintenance steps include:

Inspecting for leaks or product buildup

Replacing worn seals before failure occurs

Greasing bearings according to manufacturer recommendations

For food and pharma, always be sure your seals suit your application.

3. Verify Shaft Alignment & Balance

Misaligned shafts cause vibration, noise, and premature wear. Regularly check for:

Proper shaft positioning

Signs of imbalance

Excessive vibration during operation

If imbalance is detected, impellers may need rebalancing or replacement.

4. Monitor Motors & Drives

Mixer performance depends on reliable power. Maintenance checks include:

Inspecting gearboxes for oil levels and leaks

Verifying motor amperage draw

Testing VFDs for proper speed control

Ensuring explosion-proof motors remain compliant in hazardous environments

5. Clean & Sanitize Equipment

In food, beverage, and pharmaceutical applications, mixers must be kept sanitary. Best practices:

Implement CIP (clean-in-place) systems where required

Request appropriate finishes (eg. Ra and electropolished finishes) for easy cleaning

Follow FDA and GMP cleaning protocols

See Dynamix’s Food & Beverage Mixing Solutions for sanitary mixer options.

6. Maintain Spare Parts Inventory

Unexpected downtime can be minimized by stocking critical spare parts such as:

Impellers

Seals

Bearings

Gear reducers

Work with your supplier to set up a preventative parts program.

Benefits of a Preventative Maintenance Program

Reduced downtime – fewer emergency breakdowns

Improved efficiency – consistent energy use and throughput

Extended equipment lifespan – mixers last years longer when maintained

Regulatory compliance – GMP/FDA audits are easier with documented maintenance records

For engineering support, visit Dynamix’s Mixer Sizing & Maintenance Guide.

Final Thoughts

Preventative maintenance is an investment in efficiency, reliability, and compliance. By regularly inspecting impellers, seals, bearings, motors, and shafts and by implementing proper cleaning and spare parts management, you can extend the lifespan of your industrial mixers and avoid costly downtime.

For expert maintenance guidance and custom mixer support, contact Dynamix Agitators. Our engineering team specializes in keeping industrial mixers performing at their peak.

FAQ's

How Baffle Arrangement Improves Industrial Mixing

Do I need baffles in my Mixing Tank? Yes! While

Preventative Mixer Maintenance: A Checklist for Industrial Mixer Care

Industrial mixers are critical assets in chemical, food, pharmaceutical, and

Environmental Factors To Consider When Designing a Mixer

Why Environment Matters in Mixer Designs In the industrial

Other Recent In The Mix Articles:

Search :

SELECT THE BLOG CATEGORY BELOW

Categories

- Coal Mining (1)

- Crop Protection (1)

- Dynamix Products (7)

- Explosion Proof Motors (1)

- Fertilizer Mixer (1)

- Hand Sanitizers (1)

- Industrial Mixing (53)

- Mechanical Seals (1)

- Mining & Mineral Processing (1)

- Mixer Configuration (25)

- Mixing 101 (24)

- Mixing at Home (5)

- Mixing Principles in Play (9)

- Oil & Gas (1)

- Tank Configuration (4)

- Tote Mixing (2)

- Update (1)

- Water Treatment (28)

- Water Treatment Books (6)

- Water Treatment Innovation (13)

WHAT OUR CUSTOMERS ARE SAYING

Keep up with what's new at Dynamix

Subscribe to our newsletter for helpful technical publications and industry announcements.